Corrosion Protection

Dealers in key saltwater markets continue to point to Mercury's corrosion protection as one of the main reasons for their business growth. Tom Papesh, owner of York Road Marine in Florida, has been in the marine business for 30 years and says Mercury continues to win over customers in Southwest Florida because of their commitment to corrosion protection.

Rick Buckner from Nautical Ventures explains why he’s seeing fewer Mercury engines in his service area with corrosion issues.

Mercury offers superior corrosion protection versus the competition, delivering unequaled corrosion-fighting durability.

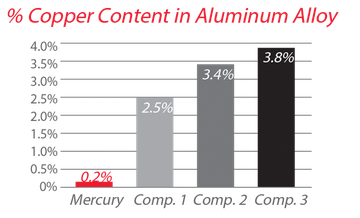

- the industry's lowest copper aluminum alloy

- two times more stainless steel than the competition in critical components

- long-term protection of vital engine parts with "Salt Shield" coating in cylinders and engine water passages

- thicker and tougher foundational barrier to seal out saltwater with the protective MercFusion Paint System

- the only company to offer a three-year corrosion protection warranty.

Key components receive an electro-chemical treatment called “hardcoat anodizing.” This coating increases corrosion resistance, resists wear, and provides better adhesion for paint.

- Protection starts with Mercury’s exclusive low-copper aluminum alloys.

- Iridite sealing provides a corrosion-resistant barrier before paint is applied.

- Electro Deposition Paint primer creates uniform coverage that seals out the environment.

- The powder paint top coat is harder, thicker and tougher than conventional paint.

Most competitors use alloys with 2% to 4% copper content which will corrode faster than our Mercalloy®, XK360 or A356 alloys.

Alloys are a combination of aluminum, copper, silicon, and other elements. When immersed in water, electrons begin to flow within the material. Aluminum is corroded by the presence of copper. Low copper content reduces the opportunity for that interaction resulting in better strength and corrosion resistance.

Yellow indicates passageways treated with Mercury® Salt Shield coating.

- Provides industry-leading corrosion resistance in water-cooling passages.

- Flushed into the powerhead and water passages to protect the engine from the inside out.

Amount of stainless steel on a four-cylinder Verado® vs. competitive 150hp four-strokes.

Mercury outboards contain at least twice the amount of stainless steel as the competition. Hardened steel is friction welded to corrosion-fighting stainless steel, producing strong and reliable shafts. This ensures saltwater only comes in contact with stainless steel.