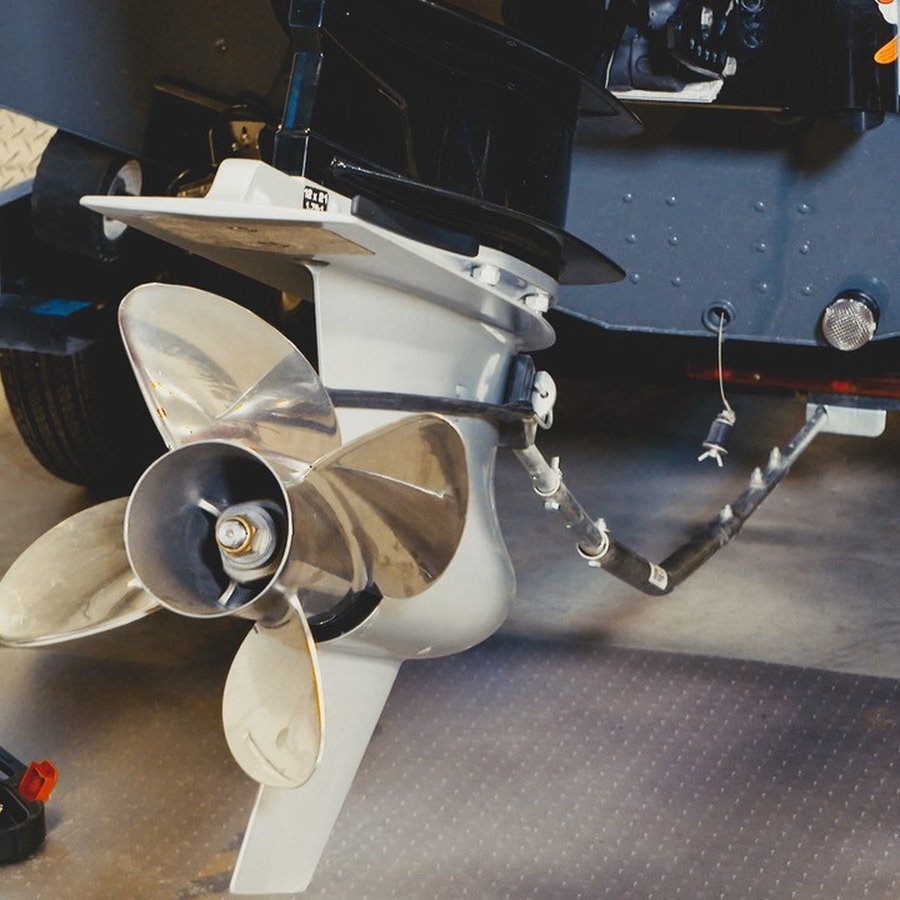

Your boat trailer is more than just a way of getting your boat to the water. It’s also an extension of your vehicle when you’re on the road. And as such, it requires working tail lights to ensure that fellow motorists can see you clearly and know immediately when you are going to stop or turn.

Maintaining working trailer lights is not just common courtesy. It’s the law, and you don’t want to start or end your day on the water with a citation for a non-functioning tail light.

Luckily, most tail-light issues are caused by a faulty incandescent bulb. In this Mercury Quick Tip Video, we show you how to complete this simple trailer maintenance task in a way that will ensure your tail lights work properly and your bulbs will last as long as possible.

To do it right, you’ll need a screwdriver (most tail-light covers are held on with Phillips screws) and a new bulb of the correct type, of course, as well as latex gloves and dielectric grease (sometimes called electrical grease). These items are available from any auto parts or marine retailer, and it’s a great practice to keep a sealed bag with these items in your tow rig or boat at all times in case a bulb goes out while you’re away from home.

The process is easy, and it will only take you a few minutes.

- Unplug your lights from the tow vehicle. Then use the screwdriver to remove the light cover and the burned-out bulb.

- Next – and this is important – put on your disposable latex gloves before removing the new bulb from its packaging. If you handle the bulb with your bare hands, your skin will leave oils and dirt on the bulb, which can drastically reduce its useful life.

- Put a little dielectric grease on the metal base of the bulb and spread it around with your gloved finger, taking care to ensure that you don’t get any grease on the glass portion of the bulb. The grease helps prevent corrosion and promotes a good electrical connection.

- With your clean glove, install the bulb into the fixture so that it’s fully seated.

- Plug your lights back in, start the tow vehicle and test your blinkers, nighttime running lights and brake lights. You can do it alone, but it’s much easier and quicker with a helper. And don’t just check the light you replaced. Check the rest of the trailer lights as well. If any other lights stop working after you’ve replaced the non-working bulb, it could indicate a short somewhere in the system.

- Once you’ve confirmed everything is working properly, reinstall the cover. Don’t overtighten the screws as that can easily crack the cover or strip out the screw holes, especially on older light kits.

All trailers will need a new bulb from time to time, but if you have recurring issues such as the lights failing intermittently or frequently burning out bulbs, it might be an indicator of a more complicated problem. In that case, depending on your skill level and time, you could use a test light and multimeter to isolate and fix the problem, or just install a whole new light kit. Most marine retailers stock affordable, easy-to-install light kits for a wide variety of trailers, and many of these kits feature sealed LED lights that will last for years with little or no maintenance. Or, you can always take it to your local authorized Mercury dealer and let a trained service team sort out the issue. They can even service the trailer from tongue to tail light, if needed.