Sport Series

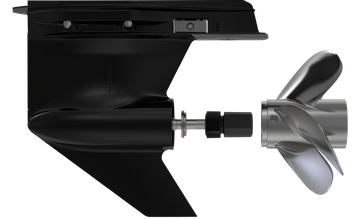

Bravo Two® – Aluminium

Hold steady through twists and turns.

- Available pitches 11, 13, 15, 17, 19, 21, 23

- Rotation LH, RH

- Performance vent system (PVS) No

- Boat types Commercial Workboat, Cruiser, Houseboat, Runabout - cuddy

- Number of blades 3

- Material Mercalloy

- Fits Bravo Two drives

Flo-Torq SSR

The Flo-Torq SSR utilizes Mercury’s proven Soft-Shift Rubber technology in a quiet hub kit that provides an NVH upgrade for Flo-Torq II hub applications where the maximum reduction of noise, vibration, and harshness is desired.

SSR

Helps preventing shifting noise and propeller rattle while providing maximum durability for smaller and mid-range horsepower outboards.

SSR Solid

Helps prevent shifting noise and propeller rattle while providing maximum durability in higher performance applications with 1” propeller shaft.

SSR HD

Helps prevent shifting noise and propeller rattle while providing maximum durability in higher performance applications with 1.25” propeller shaft.

Mercalloy®: Patented Performance

We couldn't find an aluminium alloy good enough for our propellers. So we invented one: Mercalloy Aluminium. So unique it’s patented, Mercalloy makes for higher-strength castings. Which allows for thinner blades that create less drag. Result? Optimal performance, optimal durability, better boating.

Built with pride in Fond du Lac, Wisconsin, USA. Trusted everywhere.

How do you make a Mercury® propeller? One exacting step at a time. It starts with a prop mold. Cast in specially engineered hot wax using a 5,000-year-old technique. Reinforced with two ceramic finishes in an application process that takes two full days. Steam-heated in an autoclave at 163 degrees Celsius and 100 PSI of pressure. And finally placed in a burnout furnace at more than 1000 degrees Celsius – a heat that requires employees to wear aluminised protective clothing. Strengthened and shock-proofed, the mold is ready. Liquid stainless steel now fills the cavity, heated to 1649 degrees celsius and dispensed in 23kg dollops. Over two hundred and twenty five kilograms of the molten metal pass through, creating 24 Mercury propellers. The freshly cast props cool on carts for about an hour. Then jackhammer-like knockout machines, abrasive saws, and sandblasters remove all traces of residual ceramic and oxidation. Machinists hone and prepare props for specific applications. And grinders thin leading blade edges and sand other areas. Next step: surface refinement. Two hours in a drag finish machine smoothes peaks and valleys, creating the matte finish of a Bravo Three® or pod-drive prop. Other propellers move on to a burnishing stage, gaining a high-luster finish. Fitting props with Performance Vent System plugs is the final step. They are now ready to be customised for better hole shot – and to deliver the superior performance Mercury owners around the world count on.

A Higher Grade of Performance

Mercury transforms aluminium and stainless steel into the highest-quality, best-performing, most-durable marine propellers in the world. Also the best-selling, no surprise. Our experience, expertise, and proprietary technologies – Flo Torq®, Mercalloy®, X7® alloy, and PVS® (Performance Vent System) – give you a true competitive advantage. For best overall boat performance, there's no substitute for a Mercury Propeller.